Want to know more about this project?

Drop us a line!

A Food and Beverage company, focused on industrial production of fresh patisserie, had a great deal in finding the perfect fit between stock availability and near-to-real-time manufacturing to guarantee products’ freshness. The company required a fresh food production planning system to forecast and better distribute efforts.

In particular, given the high variety of SKUs in the portfolio and a strong irregularity in the demand for most of the products (associated, in some cases, with seasonal patterns) the production effort was uneven with, consequently, significant endeavour by employees to manage eventually unexpected sales and guarantee delivery time.

The context of our client made manually organising production complex. Hence, the company wanted to leverage an automated system for fresh food production planning, based on sales trends and product availability.

Given the high variability in demand, the solution could not be a simple algorithm related to a predefined minimum level of products in stock.

The request was to define the SKUs (as well as the amounts) to produce on the basis of past trends in order to get the correct indication of quantities, time by time, and, as a consequence, plan in advance and better distribute workers’ efforts.

Relying on last year’s data and integrating them into the Data Understanding module of FactorAI, we built all the indicators needed to analyse picks and trends in the company’s production.

First things first: from the ups and downs of the stock, production and sales could be easily extracted. Given the fact that forecasting is time-dependent, all these observations have been transformed into Time Series, with one day as the sequence space.

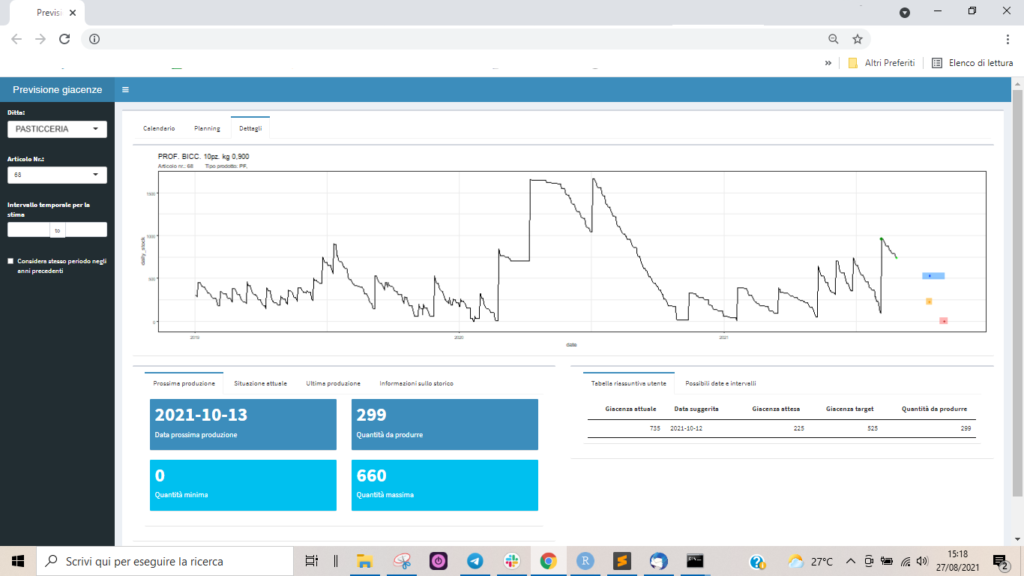

The analysis of the time series went through levels, trying to reduce the impact of the high amount of noise encountered. The objective was to extract the ideal minimum level to adopt per each SKU on one side and, on the other hand, to identify systematic components for the modelling.

The dashboard of the SPC module showed to plant manager and the organisation management graphs with:

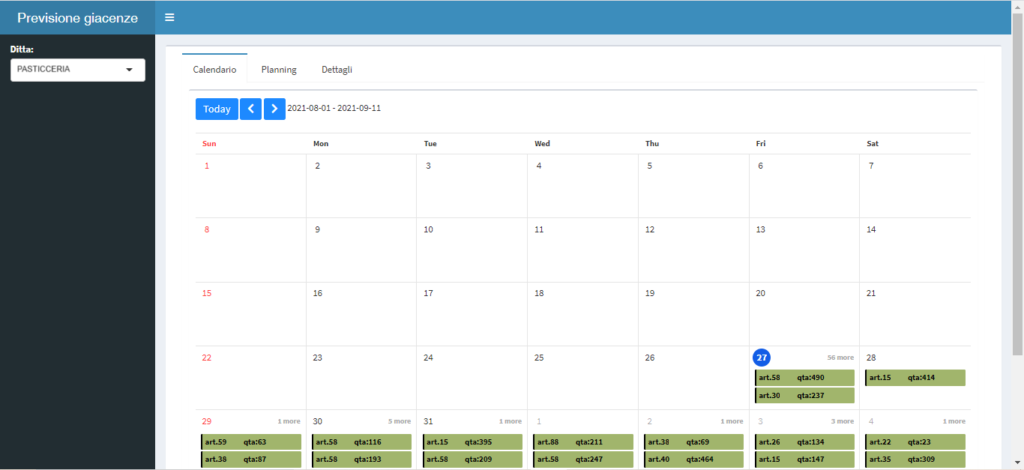

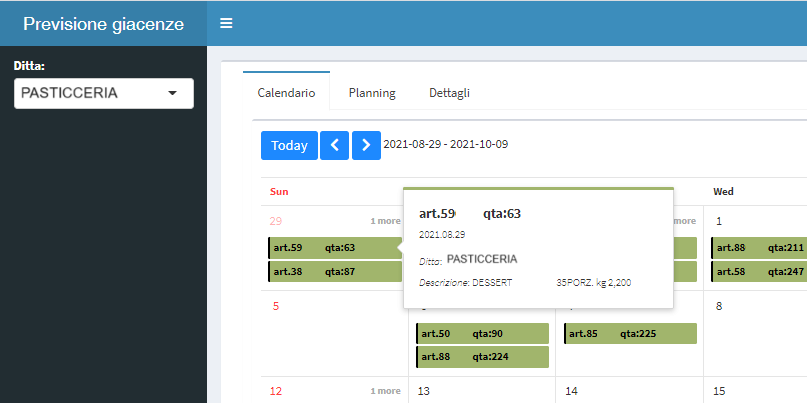

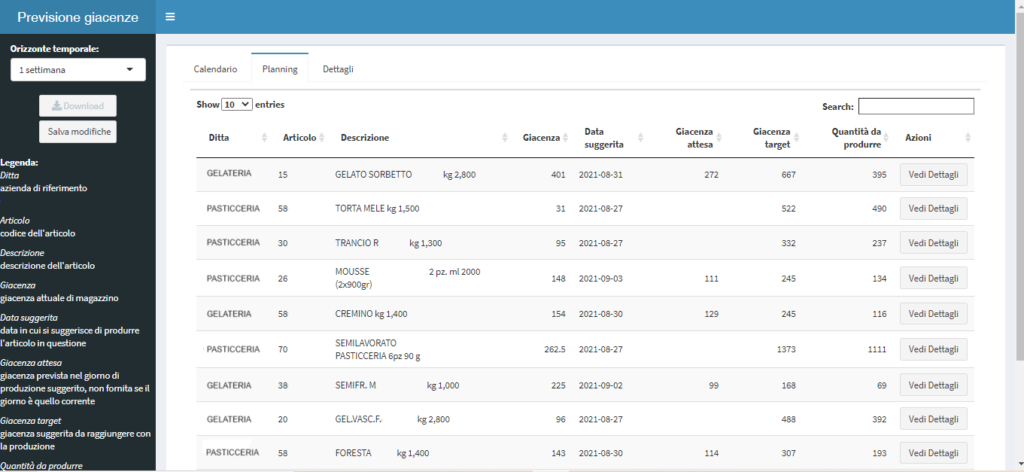

The main challenge in this prediction was to identify a modelling approach that could work on irregularities as well as on existing patterns. The AI modelling of the time series allowed to develop a planner with a calendar, showing the prediction of what SKU to produce and in which amount. The planner included for each SKU:

Following any new production, once a first delivery is done, the model analyses the pattern and predicts the next production date. Given the irregularity in orders and delivery time series, the AI engine constantly adapts itself to the evolution of orders and stock inventory, providing an updated due date that follows the evolving patterns.

Despite the pandemic, creating additional irregularity, the company integrated the new tool based on FactorAI as a production management system, obtaining significant advantages in work planning and the normalisationof team working shifts.

Calendar view with day-by-day plan

Calendar details about the SKU to produce

Production plan for the pre-selected time frame in the future.

Stock trends of the SKU under examination with main statistics and forecasts

Want to know more about this project?

Drop us a line!