Kode sponsors NIR2025 Rome

The 22° International Conference on NIR, a unique chance to share industrial NIR advances.

An article by Francesca Sbolgi, Data Scientist (Kode)

in collaboration with Marco Lucentini – Responsabile di Produzione (SCAM)

Roma, June 10th 2025 – Every two years, the International Council for Near Infrared Spectroscopy (ICNIRS – https://icnirs.org/) entrusts a nation with the honour of hosting the most prominent international conference dedicated to all aspects of NIR spectroscopy. This year, the world’s leading academic and industrial experts will gather in Rome.

Sponsoring NIR2025 – Rome represented an exceptional opportunity for us to showcase the latest developments in our NIR spectroscopy applications to hundreds of stakeholders, while also staying up to date with the newest advancements, ranging from theoretical frameworks to innovative applications across diverse research fields.

The program was rich and forward-looking, spanning cutting-edge instrumental solutions—from methodological and technological innovations (such as NIR imaging and miniaturised devices) to applications in a wide range of sectors, including agri-food analysis, quality control, clinical diagnostics, and pharmaceutical technologies. The agenda also included chemometric modelling of spectroscopic data and hyperspectral images.

NIR applications are inherently multidisciplinary, drawing upon expertise from various scientific domains. While NIR spectroscopy has long been recognised as a valuable alternative to classical analytical methods, its adoption in industrial assembly line production remains relatively limited.

Deploying spectroscopic probes in industrial processes requires not only expertise in chemometrics and spectroscopy but also a deep understanding of the specific characteristics of industrial production systems and performance data analysis. This combination illustrates both the complexity and the significant practical advantages of meaningful NIR applications in real-world operations.

Indeed, there are many fields where NIR can be effectively applied—from food and beverage (e.g., meat, milk, and agricultural products) to a wide range of benefits it can deliver, including real-time product quality monitoring and process control.

After presenting the SpectralizeR solution at the Italian NIR spectroscopy conference last year, we have been excited to bring to NIR2025 in Rome the results of a full year of applying real-time quality control to the production of organic fertilisers.

SpectralizeR and Its Distinctiveness

NIR analysis relies on near-infrared radiation, which harmlessly interacts with the sample, causing molecules to respond differently depending on the concentration of various analytes. The resulting signals are mathematically processed using artificial intelligence models, ultimately returning the concentrations of the requested analytes. This methodology does not require consumables or toxic reagents (which would then need disposal), and the product is scanned directly in-line, providing instant information without interrupting the production process.

These data, automatically integrated into a process optimisation platform—such as our tool SpectralizeR—feed into a machine learning model (combined with process indicators) capable of retrospectively linking each product characteristic, as revealed by spectroscopy, to specific plant activities. This allows the identification of necessary corrective actions and helps prevent production drifts or errors.

Currently, Kode’s SpectralizeR solution, in a customised version, is used daily by a company operating in the agronomic sector. The project was developed to monitor in real-time key characteristics of different product types at multiple stages of the production process and before bagging, thus ensuring the quality of every item released to the market.

Objectives of Using SpectralizeR in the Industrial Sector

As one of the first in its field, SCAM—a leading company in the production of organo-mineral fertilizers with certified Environmental Product Declaration (EPD), and at the forefront in the formulation and packaging of biostimulants, specialty fertilizers, and crop protection products—has decided to implement NIR sensors to enable a real-time monitoring system across its entire production process.

For products with such high value in terms of environmental sustainability, which support a high quantitative and qualitative level of agricultural production, the company aims to ensure not only the characteristics of the humified organic components, but also the high performance and effectiveness of the product in every single bag released to the market.

Therefore, SCAM has chosen to install a detection system based on NIR probes at a critical point in the plant, in order to monitor this key aspect during the granulation process.

In-line Production Application

SCAM’s main requirement is to use NIR probes directly on the production line, where it is essential that the readings from these probes are as precise and accurate as possible. In particular, moisture values need to be measured within a very narrow range, with a maximum acceptable error of 0.3%.

For this reason, the first key step in the project was a thorough analysis and calibration phase of the probe results. Spectral fingerprints collected from the probes were acquired and stored over time, and based on this dataset, an Applicability Domain model was developed for each product type, assigning a validity score to every acquired spectrum. This model is necessary to select acceptable spectra and distinguish valid product acquisitions from invalid ones—such as end-of-production samples or out-of-score spectra caused by production issues. Based on this model, an operational alerting system was developed for SCAM personnel.

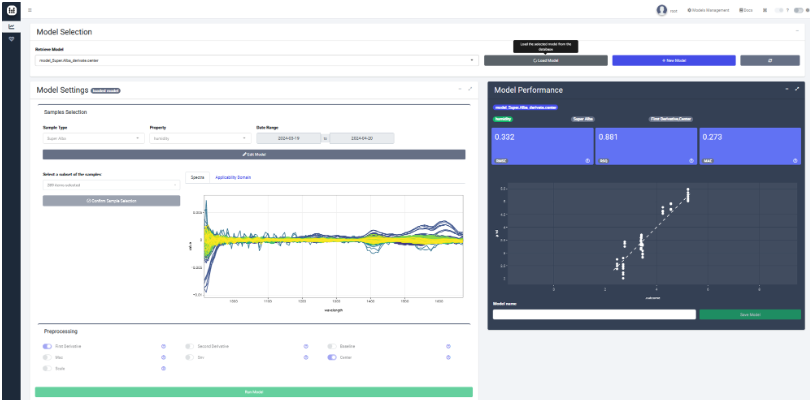

Thanks to the Applicability Domain model, Kode’s data science team proceeded to build an additional predictive chemometric model. Through parameter tuning and an in-depth training phase, this model is capable of transforming a spectral fingerprint into a concrete quantification and qualification of the sample’s moisture level, presented to the operator in a dashboard in either textual or graphical format.

A Dedicated Application for Operators and Lab Personnel

Since the goal of this project is not only to acquire accurate and well-calibrated data from the probes, but also to enable operators to take meaningful action on the production line, the system has been integrated into a custom software solution with operational features tailored to the daily needs of SCAM’s fertiliser production.

Built upon the base version of SpectralizeR, this is a web-based application that can be accessed from any workstation (control room, quality lab, management station…) equipped with a computer.

The application allows production line operators to:

- Analyze historical data: by selecting a specific SKU and a time range, retrieve moisture values in both graphical and tabular formats

- Monitor moisture levels in real time directly from the production line

- Prevent drift: receive early warnings of potential specification limit deviations (via predictive modelling and/or Statistical Process Control rules)

For lab chemists, the system provides a dedicated section to manage existing calibration models, as well as to create new ones and retrain those already in use.

The Results

SCAM is a cutting-edge manufacturing company in the fertiliser sector, distinguished by its pioneering commitment to producing Sustainable Organo-Mineral Fertilisers, fully aligned with the European Green Deal directives. The production plant, located in Modena and covering 147,000 square meters, is in constant evolution through both structural and intangible investments.

The pursuit of innovative solutions that continuously add value to the marketed product has been the driving force behind the decision to adopt Artificial Intelligence for a forward-thinking approach to operations. This new path will allow SCAM to harness the vast amount of data generated during production to harmonise and optimize processes, ensuring the highest quality of its products.

Today, SCAM has fully integrated the solution into its production operations and can already guarantee the quality of each specific product released to the market.

For more info: SpectralizeR